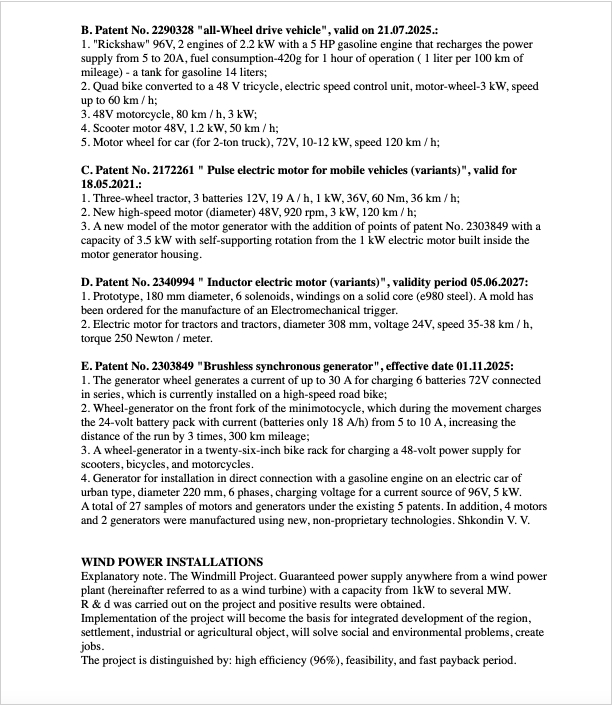

CONVENCTIONAL ELECTRIC MOTORS

SHKONDIN MOTOR WHEEL (SMW)

Li-ion or sodium sulfur batteries, strict voltage parameters

Simple, cheap and reliable low-voltage helium batteries with supply voltages from 6 to 96 volts

30%-50% (2-3 times lower)

Mileage distance without recharging

180%-200% (80-100% more powerful)

Dust and moisture resistance

Demanding to operating conditions, ambient temperature (cooling is required)

Capable of operating underwater, at elevated ambient temperatures and in all conditions of dust, dirt, corrosive environments

Motor heating during operation

Complex control is required, microprocessors with software

A simple pulse-width modulator, small and cheap. No differentiation unit

Reliability (warranty period)

Product warranty of 5-10 years

High maintenance costs due to complex electronic control and differentiation unit

Virtually no service required

2-3 times lower than conventional motors

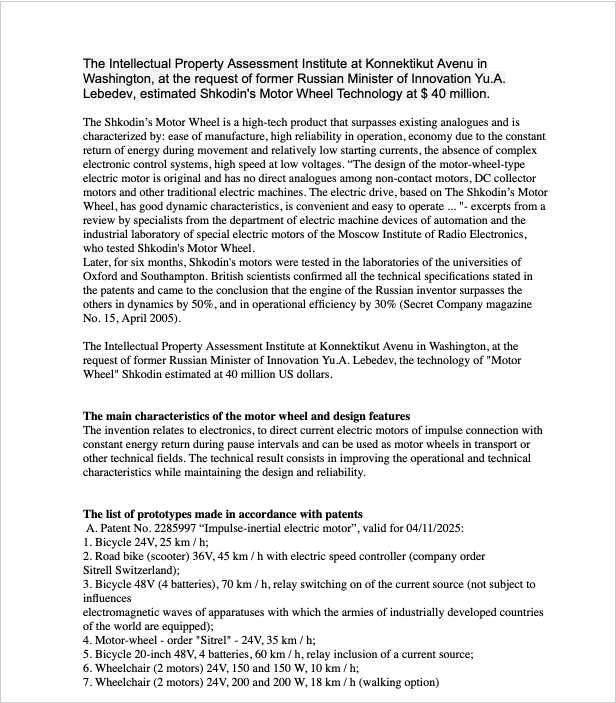

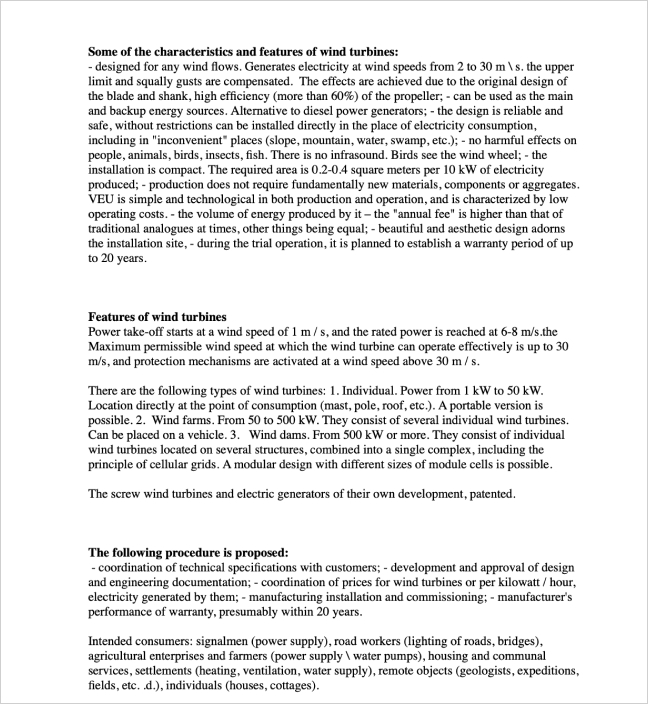

All these technical advantages, combined with the simplicity of the design of the Shkondin motor wheel, make its production an extremely profitable industrial product with a high degree of competitiveness.

MATERIAL CONSUMPTIONCompared to conventional engines, the material intensity of SMW is 4-8 times lower and the weight is 30-50% lower. Thus, the material cost of SMW will be lower by at least 50%

DESIGN SIMPLICITYThe design simplicity of the SMW, is only 5 nodes in contrast to 13-18 nodes in traditional engines. In this regard, high manufacturability of production and assembly, and as a result – high reliability and maintainability of the product. Thus, the manufacturability increases by 2.5 times.

LOW PRODUCTION COSTSThe minimum number of technological steps determines low production costs. This means saving on human resources, less number of machines and less power consumption in production. Accordingly, the cost of production of one SMW will be 2-3 times lower.

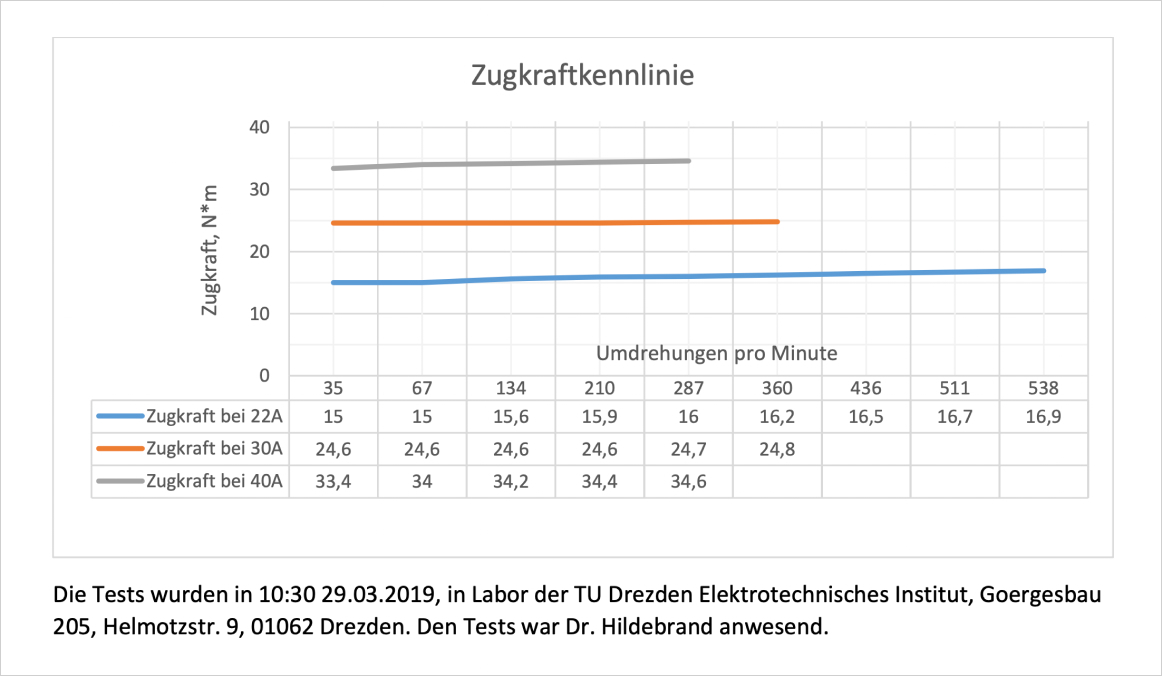

iNCREASED TORQUE UP TO 50%

The diametrically opposed arrangement of the electromagnets contributes to a significant increase in torque.

INCREASED PERFORMANCEIncrease of the following indicators: range - up to 30%, maximum speed - up to 35%, acceleration characteristics - up to 40%.

ALL BATTERY TYPESIt is also possible to use any battery types with supply voltage consisting of 6 to 96 volts.

DURABILITYDurability is increased fivefold as demonstrated by Shkondin motor test conducted at the hero cycle factory llaboratory in India, in this illustrative example the motor was submerged in water for one hour, then operated continiously on a test stand for nine days. This rigorous testing simulates a mileage of 5000 km showcasing the motors, exceptional endurance and reliability.

RESISTANT TO AGGRESSIVE ENVIRONMENTSShkondin motor is capable of operating under water at elevated ambient temperature and in any conditions of dust, dirt and aggressive environments. The analogs are demanding to operating conditions and ambient temperature.

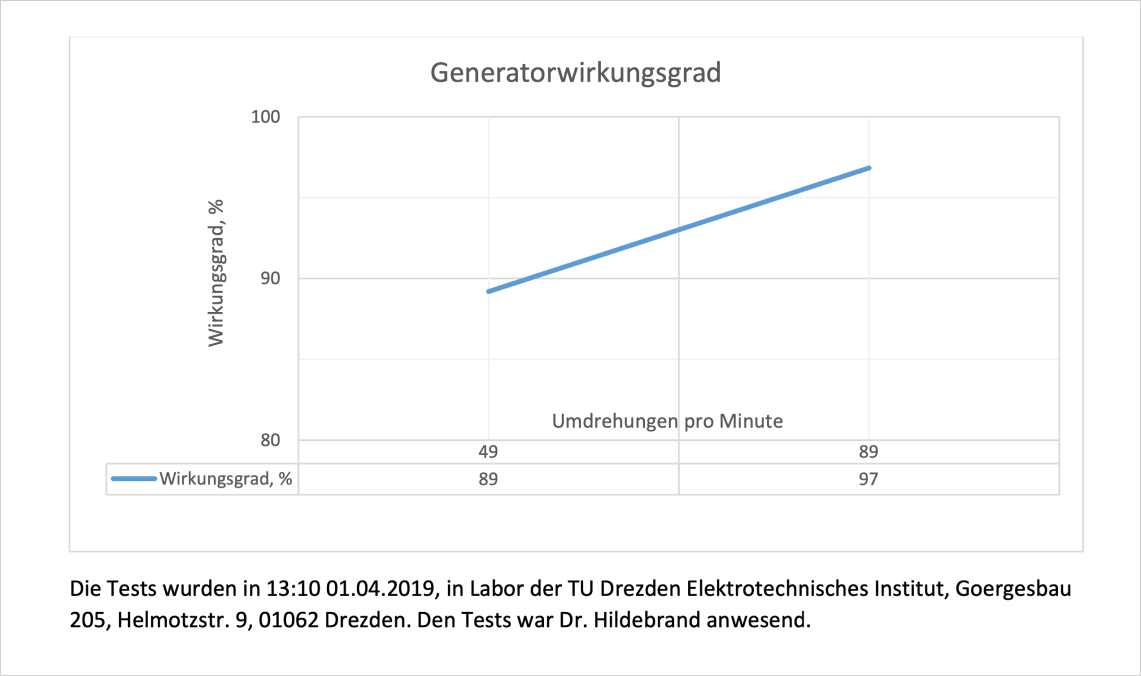

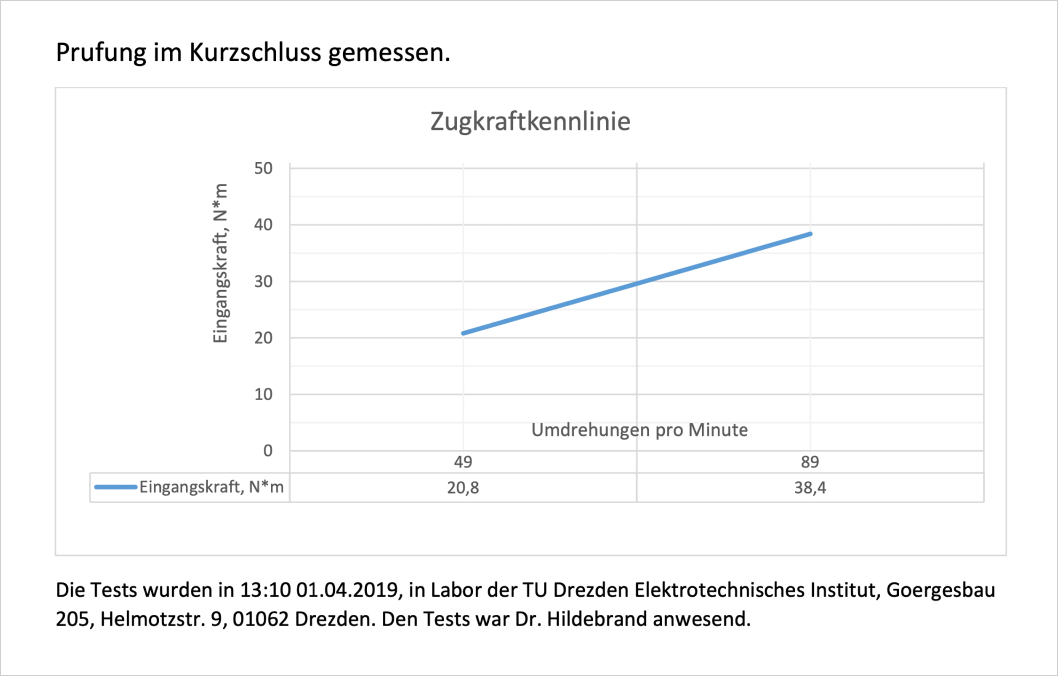

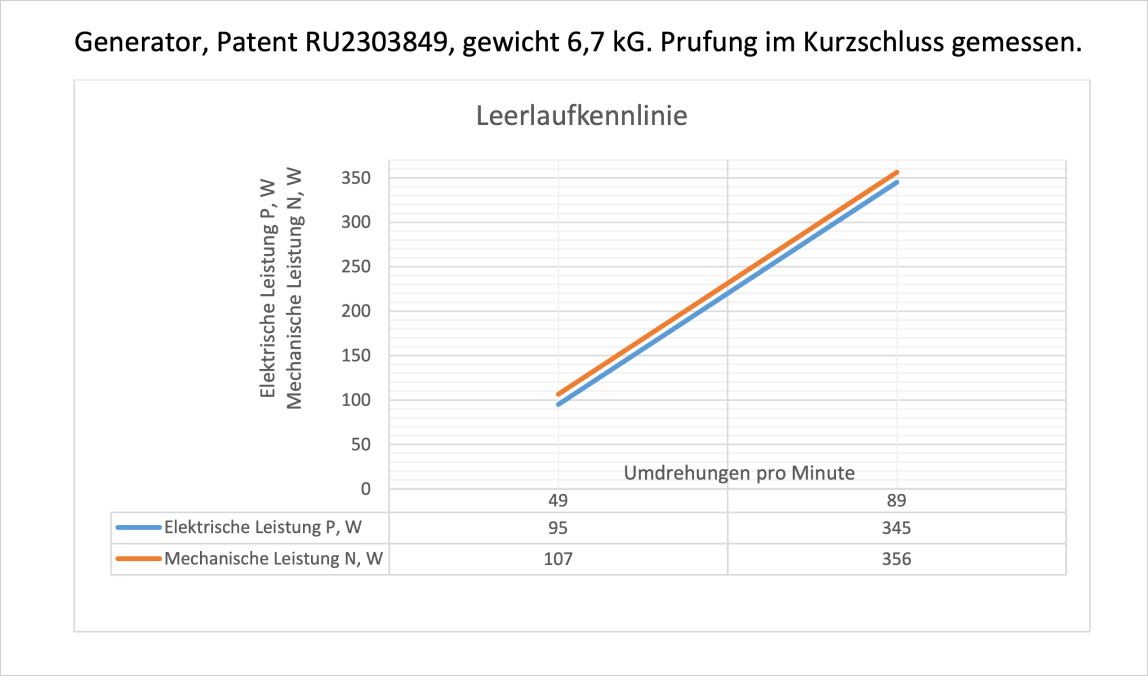

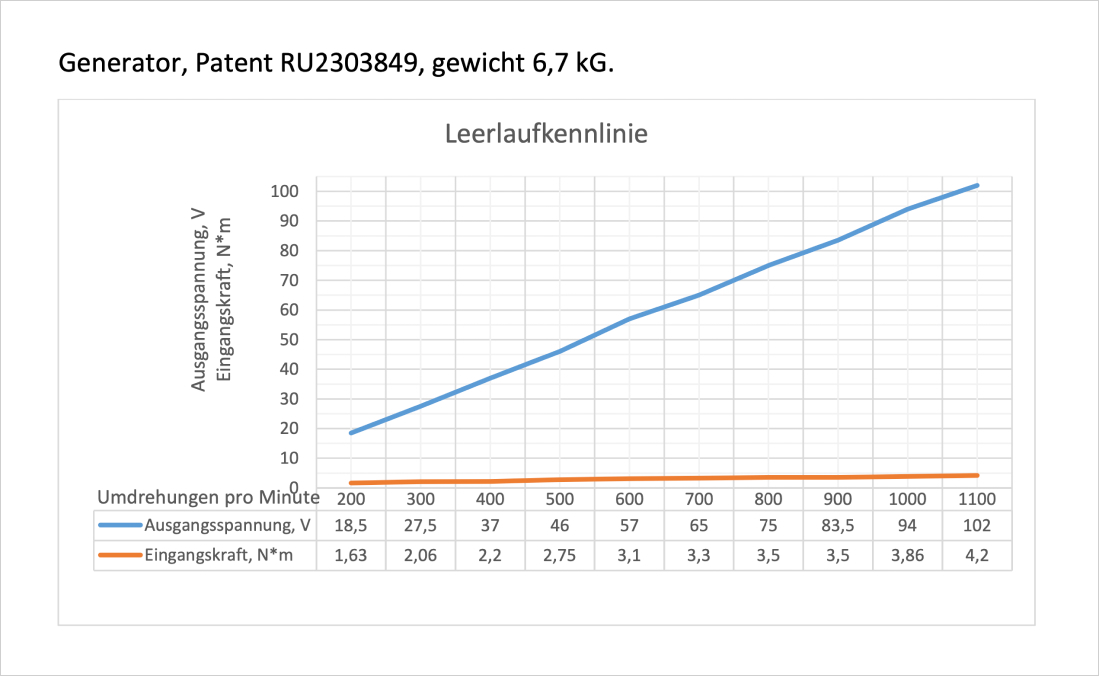

WORKS AS A GENERATORThe Shkondin motor works as a generator. As an example, if the battery on an electric bicycle is low, you can continue pedaling, replenish the charge and move again using the electric power of the motor.

NO STARTING CURRENTSThat's right, no starting currents!

RECUPERATIONDuring operation, the motor returns electricity to the battery - as an additional recharge.

LOW TEMPERATUREThe operating temperature of the Skondin motor is no higher than 70 degrees Celsius.

SIMPLE CONTROLThe Shkondin motor operates without relying on complex electronic devices such as computers, microprocessors, or software.

This design makes the Shkondin motor highly resistant to electromagnetic, ionization, and other disruptive effects. Consequently, a helicopter powered by the Shkondin engine would remain operational even in the event of a nuclear explosion or combat directed electromagnetic radiation that could otherwise disabe control systems.